Specifying Spray Polyurethane Foam Insulation in Occupied Buildings

Building Code Requirements and Fire Safety Concerns

Spray polyurethane foam insulation (SPF) is increasingly being specified due to its technical and economic advantages compared to other thermal insulation products such as foam board, fiberglass, mineral wool and cellulose. The primary reason is SPF is often the most cost-effective material to achieve compliance with new energy code requirements requiring higher R-ratings, air barriers and preventing condensation & mold growth.

Writing appropriate specifications to assure fire safety during the construction process and during the life of the building is critical for the life safety of occupants as well as minimizing liability in the event of harm to persons and property.

Fire Safety During Construction and Renovation of Buildings – An Increasing Concern

The National Fire Protection Association article Fires in Structures Under Construction, Undergoing Major Renovation, or Being Demolished, April, 2017 indicates there was an annual average of 6,310 reported fires in buildings under construction or being renovated between 2010 and 2014. Primary causes were related to hot work, smoking materials, intentional ignition, heating equipment and cooking equipment. There was an annual average of 9 civilian deaths, 62 civilian injuries and $150,000,000 in direct property damage.

An increasing concern regarding fire safety during construction and renovation is due to:

A. Increasing quantities of installed combustible building products.

B. Increasing carelessness and apathy of construction workers.

C. Increasing arson.

Fire Safety Guidance from the Spray Polyurethane Foam Alliance (SPFA)

SFPA is the trade association of spray foam insulation manufacturers and contractors. SFPA-126 Thermal Barriers and Ignition Barriers for the Spray Polyurethane Foam Industry provides fire safety guidance and building code requirements for SPF.

Page 6 in this document provides the following guidance as to why it is increasingly being acknowledged that the greatest fire hazard of SPF is during the construction process when the SPF is unprotected.

“When exposed to fire sources, such as trash fires, welding arcs, cutting torches or red-hot metal, unprotected SPF can ignite and may result in a flash fire. Although burning SPF will form a surface layer of less flammable char, the initial burning can produce combustible gases and black smoke. In confined interiors, these combustible gases can accumulate and ignite, resulting in flashover, a dangerous fire situation. Under these conditions, additional foam and other combustibles can become involved in the fire, creating additional combustible gases and feeding the fire.”

International Building Code and International Residential Code requirements for foam insulation

The fire safety requirements of all editions of the International Building Code (IBC) and Residential Building Code (IRC) for spray foam and foam board insulation when installed in occupied spaces consist of two parts:

1. In most applications the foam insulation must have a Flame Spread Index not greater than 75 and a Smoke Developed Index not greater than 450 when tested in accordance with ASTM E-84, and

2. The foam insulation must meet either of the following requirements:

A. Be separated from the building interior (occupants) by ½ inch gypsum board or an equivalent

15-minute thermal barrier, fire-protective covering that meets the requirements of NFPA 275, or

B. Comply with the Special Approval Section 2603.9 of the International Building Code or the Special Approval Section R316.6 of the International Residential Code when installed exposed or with fire-protective coverings that pass NFPA 286, UL 1715, FM 4880 or UL 1040. Such products are termed Alternative Thermal Barrier Assemblies.

Certain exterior wall assemblies in Types I, II, III and IV must also comply with NFPA 285.

Limitations of small-scale laboratory tests for measuring large-scale fire performance

Virtually all foam insulation meets the IBC and IRC requirements for a maximum 75 Flame Spread Index and maximum 450 Smoke Development Index. Results of large-scale fire tests and actual fires indicate that most foam insulation having a Flame Spread Index as low as 23 can result in flashover and fire growth in less than 3 minutes when not covered with gypsum board, an equivalent 15-minute thermal barrier, or pass one of the code-designated, large-scale fire tests when tested exposed.

This is the reason the IBC and IRC require SPF to be separated from building occupants by ½ inch gypsum board or an equivalent 15-minute thermal barrier unless the SPF, either exposed or covered with a fire protective material, is classified as an Alternative Thermal Barrier Assembly.

Limitations of gypsum board for fire-protecting foam insulation

Two circumstances exist where SPF presents a potential fire hazard even though gypsum board has been specified as the code-compliant fire protection:

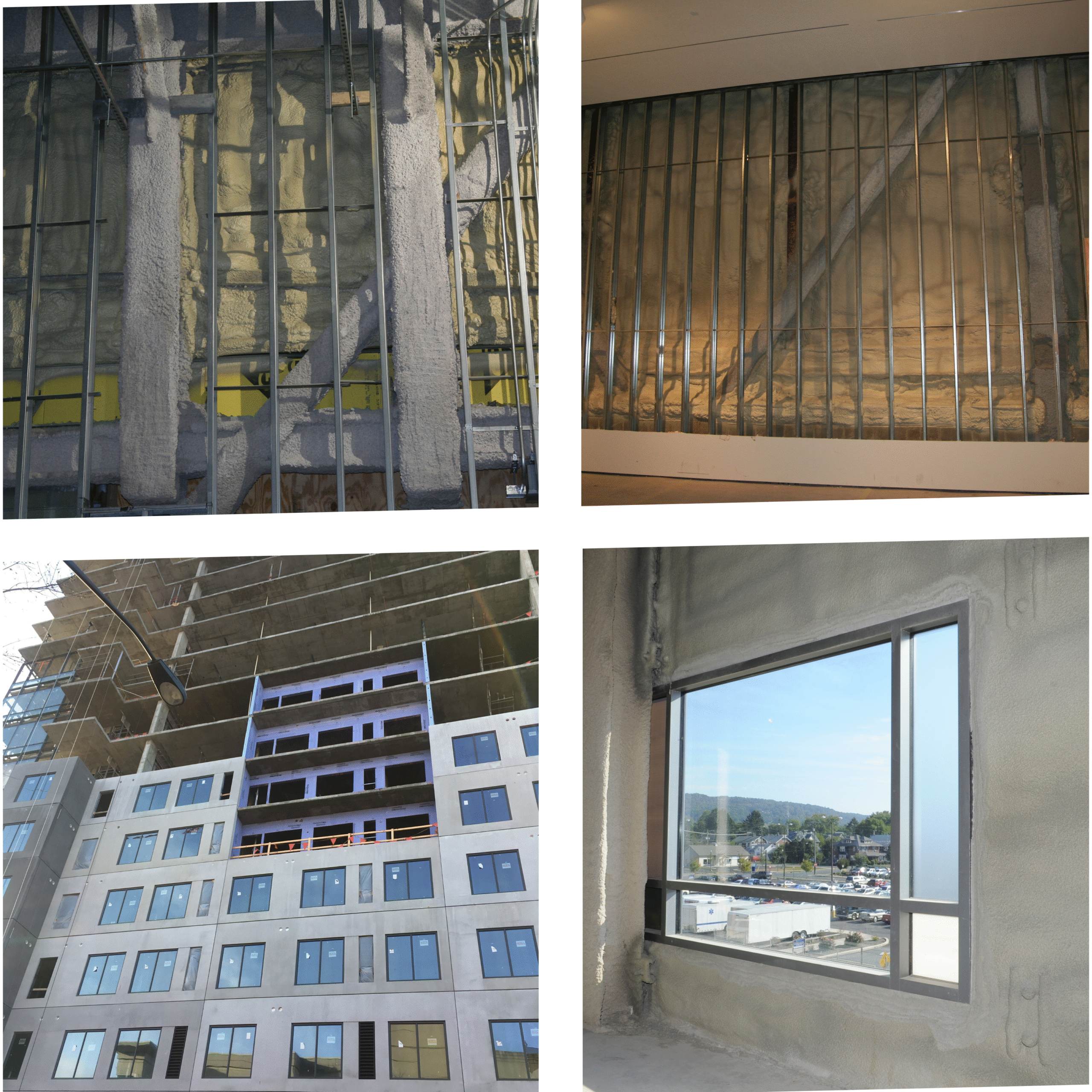

1. During the construction process prior to gypsum board installation

Combustible building materials are significantly more susceptible to fires during the construction process than after the building is fully occupied. It is often weeks or months between the time the SPF is installed and when the gypsum board is installed as the interior finish and fire protection. In some buildings, gypsum board is not installed on walls until a new tenant installs their required electrical and communication wiring.

During these interim periods, the exposed SPF can be ignited by cutting torches, welding sparks, trash fires, vandalism or arson thus posing a significant potential fire hazard. Large-scale fire testing indicates exposed, Class A, foam insulation having a Flame Spread Index as low as 23 can result in flashover and create copious quantities of smoke in less than 3 minutes.

Two options exist to prevent such fire hazard: (1) protect the SPF immediately with gypsum board or fireproofing or (2) install SPF that has integral fire resistance and is classified as an Alternative Thermal Barrier Assembly without the necessity to install fireproofing or gypsum board.

2. During the life of the building due to air spaces between the gypsum board and the foam insulation

Since air spaces exist between the SPF and the gypsum board, electrical shortages or routine maintenance activities such as sweating copper piping can also ignite the foam in the cavity.

For these reasons, an increasing number of architects, AHJs, fire officials, and insurance organizations are requiring fire-protective coverings to be installed immediately after the SPF is sprayed or be a SPF that passes the large-scale fire tests when tested exposed.

Staycell ONE STEP® Intumescent Spray Foam Systems comply with the IBC and IRC when installed exposed without additional fire protection

Staycell ONE STEP® Intumescent Spray Foam Systems pass the UL 1715 large-scale fire test when tested exposed as listed in Evaluation Report No. B1020-1, Edition 8 published by QAI Laboratories. QAI is accredited by the International Accreditation Service, a division of the International Code Council who develop and publish the International Building Code and International Residential Code. These systems do not propagate fire nor cause flashover during the entire test period. As a result, the installation of these products provides improved fire safety during construction and redundant fire safety for the life of the building when gypsum board is subsequently installed.

Typical specification language to maximize fire safety during the construction process and during the life of the building:

To maximize fire safety during construction, ½ inch-thick gypsum board or equivalent 15-minute thermal barrier shall be installed within 24 hours after the foam insulation is installed each day. Such time period of installation is not required for foam insulation that is qualified as an Alternative Thermal Barrier Assembly when tested exposed without fire-protective coverings.

Related Products

STAYCELL ONE STEP®

502 HFO

High performance, closed-cell SPF. Qualified Alternative Thermal Barrier Assembly. No thermal barrier coating required when used in assembly specific applications.

STAYCELL® HYBRID

HFO SYSTEM

High performance, closed-cell SPF. Qualified Alternative Thermal Barrier Assembly. No thermal barrier coating required when used in assembly specific applications.

STAYCELL®

504 HFO

High yield, closed-cell SPF. Used as the base layer for the Staycell® HYBRID System and for commercial & residential applications when covered with 1/2″ gypsum board.